Weld Overlay Remanufacturing Rebuilding Worn Components with Metallurgical Strength

When components suffer from deep wear, scoring, or undersize conditions, surface coatings alone aren’t enough. That’s where weld overlay comes in—restoring lost material, reinforcing critical areas, and extending component life far beyond standard repairs.

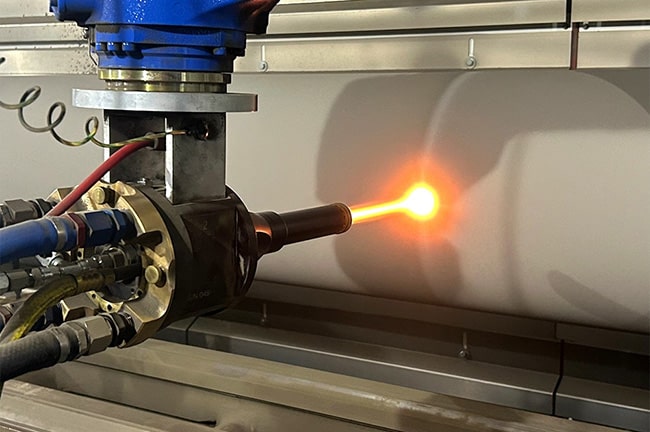

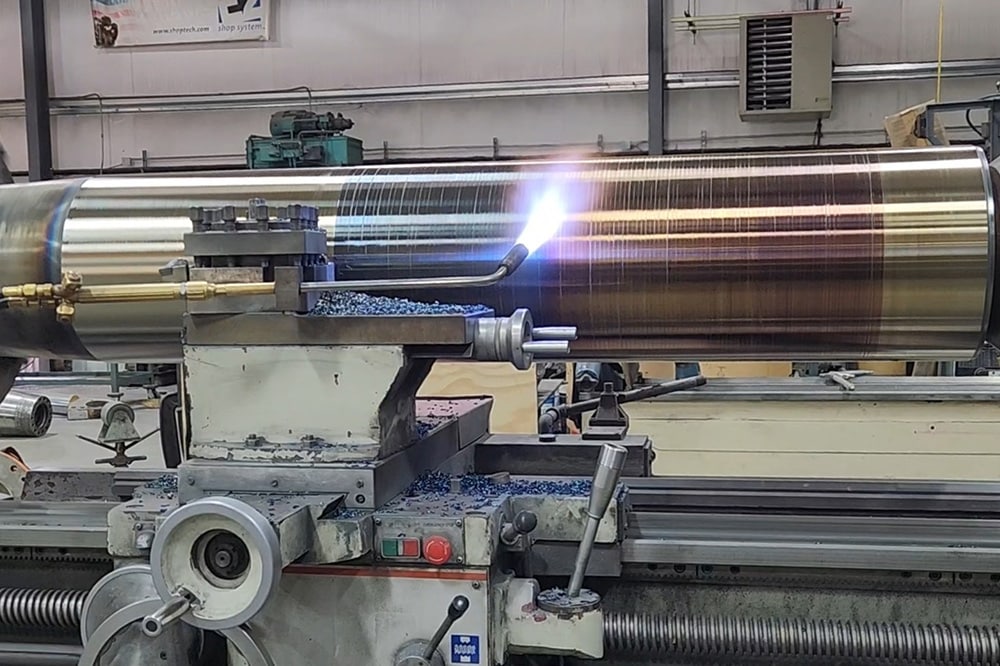

We designed our own in-house robotic and automated precision weld overlay systems using advanced submerged arc welding (SAW). Our process is engineered to rebuild and strengthen high-wear components across heavy equipment, industrial machinery, and rotating systems—preparing them for final finishing with coatings or chrome plating.

Whether you’re dealing with pivot shafts, spindles, hydraulic rods, or bearing journals, we deliver controlled, reliable material restoration designed for heavy-duty applications.

Weld Overlay Applications

- Suspension Cylinder Rods

- Wheel Spindles

- Heavy-Duty Hydraulic Cylinder Rods

- Rotating Shafts & Journals

- Pins, Sleeves, and Mechanical Drives

High Tech Reman is the authority in weld overlay

- Expertise in remanufacturing-grade overlays, not just cladding

- Proven success in mining, industrial, and oil & gas applications

- Custom-engineered, proprietary welding procedures tailored for component longevity

- Fast turnaround to reduce downtime and avoid costly replacements

Weld Overlay FAQ Topics

What is weld overlay, and how is it different from welding repair or cladding?

Weld overlay is the process of depositing new metal onto a worn or damaged surface to restore or enhance its properties. Unlike a simple weld repair that fixes isolated defects, overlaying rebuilds the surface across a controlled area, often with engineered alloys to improve strength, wear, and corrosion resistance.

What welding processes do you use (SAW, MIG, TIG, etc.)?

We use submerged arc welding (SAW) for high-deposition overlays, MIG/GMAW for precision buildup and repair, and TIG/GTAW for smaller, critical surfaces. Each process is selected based on component geometry, alloy chemistry, and service environment.

How do you control dilution and heat input?

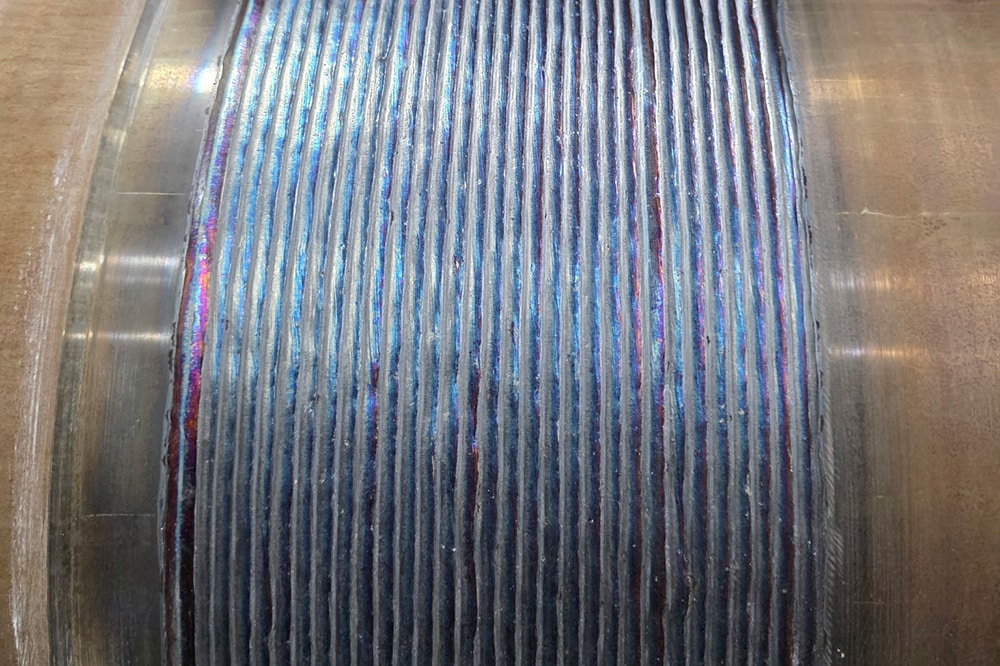

We tightly control all welding parameters, preheat, and interpass temperatures to maintain carefully targeted levels of dilution. This preserves the alloy chemistry in the overlay and minimizes cracking or hardness variation across the weld zone.

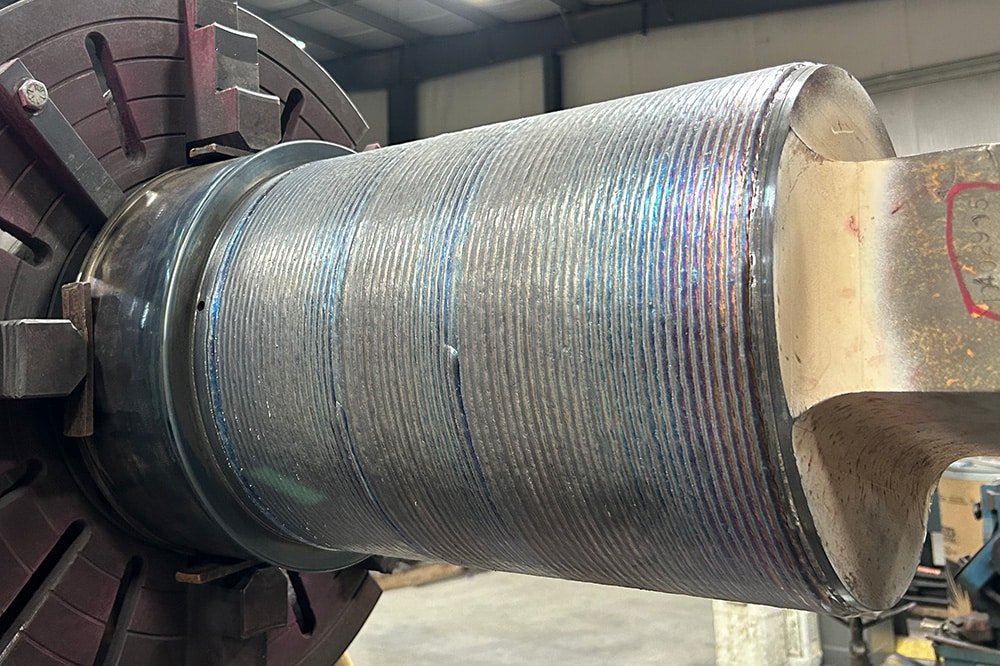

How thick can an overlay be applied?

Typical overlays range from 0.060” to over 0.500” thick, depending on design intent and repair scope. Our proprietary repairs have designated depths of repair, designed to ensure the proper metallurgical characteristics of the component are restored.

What are the most common weld overlay defects and how are they prevented?

Typical overlay defects include porosity, lack of fusion, cracks, and overlap voids. We prevent them by maintaining proper weld parameters, preheat, pitch, interpass temperatures, and in-process checks. Each component has a unique procedure for these settings.

How do you inspect overlays for quality (NDE methods)?

Overlays are inspected using visual inspection, magnetic particle testing (MT), liquid penetrant testing (PT), and ultrasonic testing (UT) where required. We document bead geometry, thickness, and coverage to verify conformance to specifications.

How do overlays interface with coatings like chrome or HVAF?

Our weld overlay chemistries are carefully engineered to ensure compatibility with finishing coatings. Each overlay provides a metallurgically sound foundation for surface treatments such as hard chrome plating and HVAF/HVOF carbide coatings. When properly finished, the overlay delivers excellent bond strength, coating adhesion, and long-term durability in demanding service environments.

What are the advantages of your proprietary overlay process compared to conventional welding?

Our proprietary High Tech Reman overlay procedures are unique for each component. They combine automated deposition control, optimized pitch geometry, and alloy-specific parameter sets. The result is consistent bead profile, uniform hardness, and minimal distortion — far exceeding conventional manual welding in precision and repeatability.

Our Services

Expansive in-house capabilities allow us to keep all facets of the chrome plating and repair process under our control.