Precision Machining & Grinding Tight Tolerances. Perfect Finishes. Ready-for-Service Components.

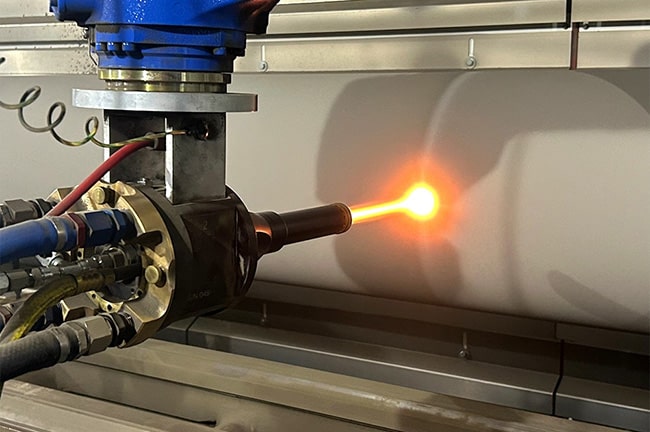

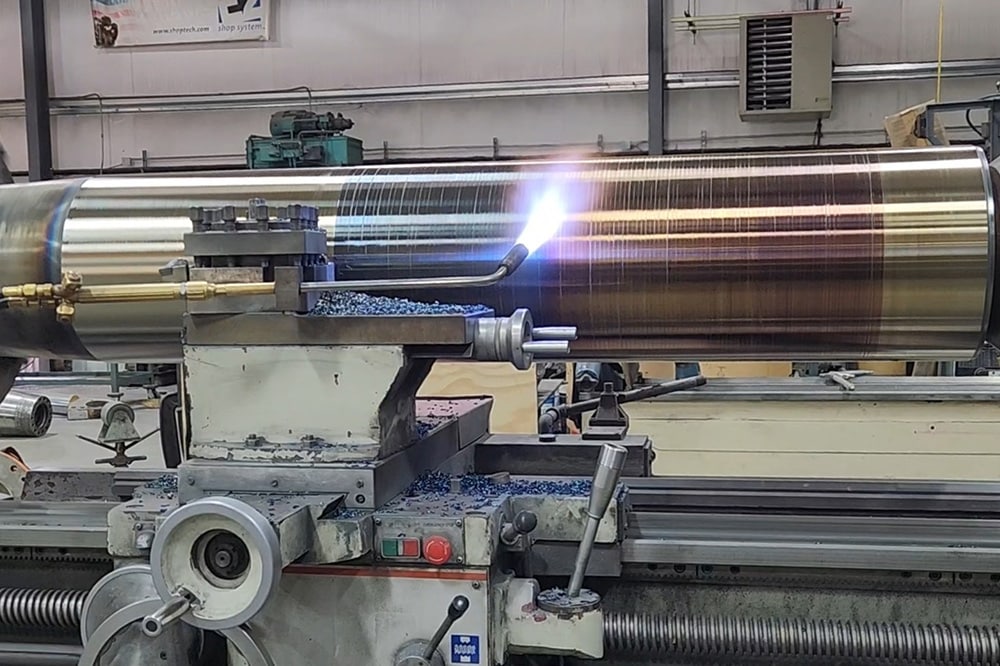

Precision machining and grinding are core elements of our engineered remanufacturing process. Whether we’re restoring hydraulic rods, spindles, shafts, or industrial rollers, our team ensures exact dimensions, surface finishes, and geometric tolerances—delivering components that meet or exceed OEM standards.

Unlike general-purpose machine shops, our machining capabilities are built around remanufactured surfaces—accounting for weld overlays, chrome plating, and thermal spray coatings. Every cut, turn, and grind is performed with reman performance in mind.

From large-diameter rollers to complex shafts and pins, we provide high-precision solutions that get your equipment back to work—fast.

Machining & Grinding Applications

- Hydraulic Cylinder Rods

- Wheel Spindles & Shafts

- Industrial Rollers (Bridle, Deflector, Idler)

- Pivot Shafts & Pins

- Sealing & Bearing Surfaces

Our Capabilities

- OD grinding for components up to 32’ length & 36” diameter

- Holding tolerances within .001” for critical fits

- Surface finishes down to 1.0 Ra for low-friction and sealing zones

- Machining of welded, sprayed, or plated surfaces with precision

- Flexibility for both one-off repairs and production batches

High Tech Reman is a Full-Service Machining & Grinding Partner

- Integrated with our weld overlay, thermal spray, and hard chrome services

- Specializing in finishing remanufactured parts—not raw stock

- Capacity for large, challenging industrial components

- Fast, controlled turnarounds with every process in-house

Our Services

Expansive in-house capabilities allow us to keep all facets of the chrome plating and repair process under our control.