Industrial Roller Remanufacturing for Aluminum ProcessingPrecision Coatings and Surface Restoration for Lightweight Metal Production

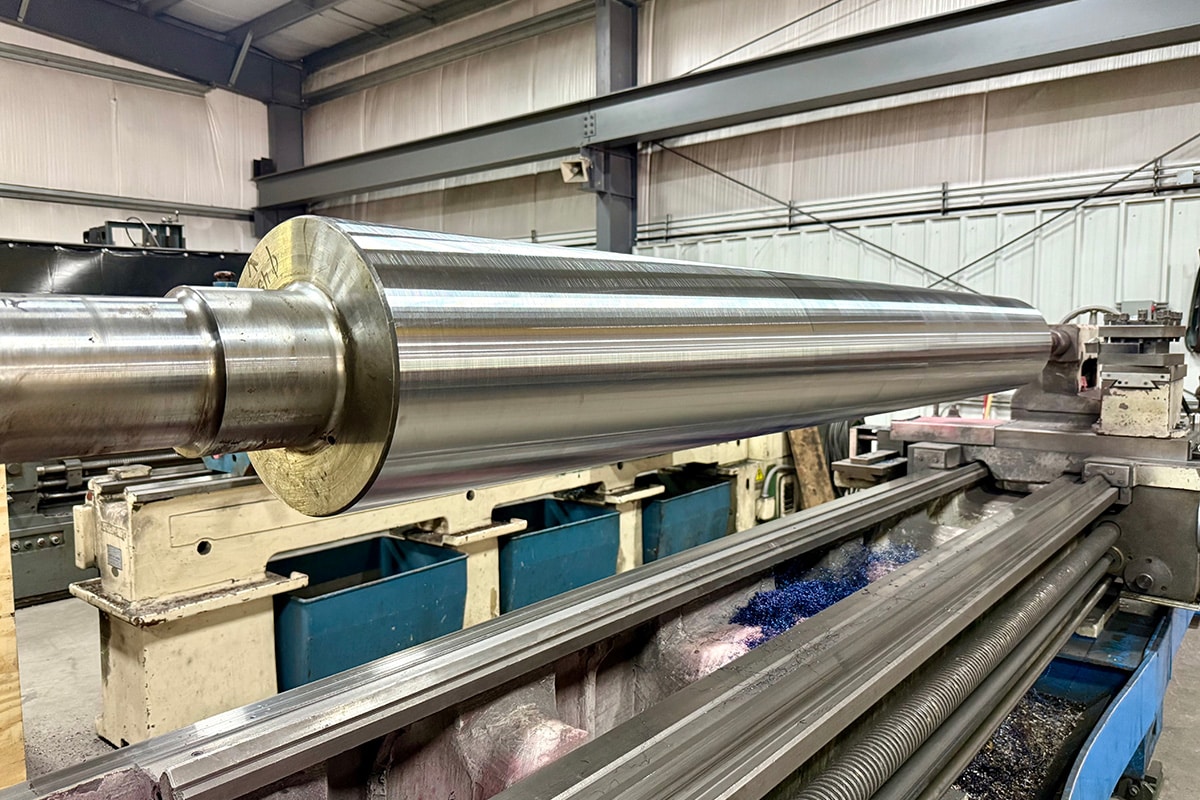

Aluminum processing lines demand exacting standards. Whether in hot or cold rolling, coil coating, or finishing lines, rollers must maintain flawless surfaces, precise tolerances, and resistance to corrosion and abrasion. Surface defects or roller wear can lead to costly product rejections, line downtime, and frequent maintenance cycles.

We offer fast turnaround, high-volume remanufacturing and resurfacing rollers for the aluminum industry—delivering advanced coating solutions and precision machining to keep your lines running smoothly. From bridle rolls to deflector rolls, we help aluminum producers and processors extend roller life, improve product quality, and reduce operational costs.

Common Rollers We Service for Aluminum Mills

- Bridle Rolls

Critical for tension control—requiring high-traction, wear-resistant surfaces. - Deflector Rolls / Guide Rolls

Ensuring accurate strip alignment through processing lines. - Pinch Rolls

Handling and feeding strip material—prone to surface wear. - Coil Handling & Support Rolls

Used in storage and transport systems—requiring durable finishes. - Idler Rolls

General support rollers needing smooth, corrosion-resistant coatings.

Our Aluminum Roller Remanufacturing Solutions

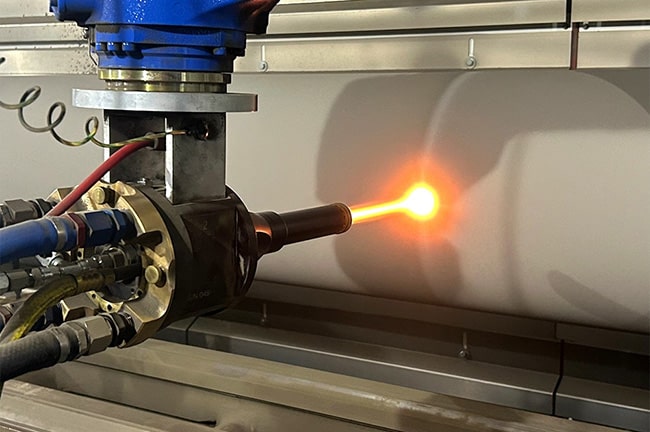

- Thermal Spray Coatings (HVAF/HVOF)

Application of tungsten or chromium carbides and specialized alloy coatings to enhance wear resistance without compromising surface finish requirements. - Hard Chrome Plating

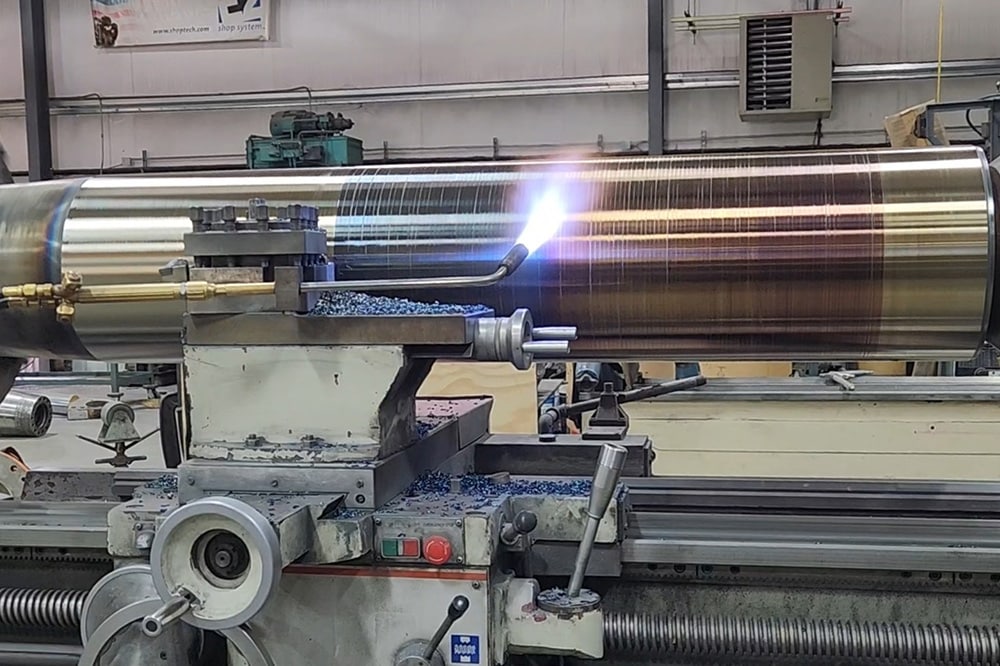

Ideal for rollers needing low-friction, corrosion-resistant surfaces in coil processing and finishing lines. - Precision Grinding

Achieving ultra-smooth finishes critical to prevent marking or scratching of aluminum strip. - Weld Overlay & Journal Repair

Restoring worn journals and bearing fits to OEM tolerances for proper line performance.

Why Aluminum Processors Choose High Tech Reman?

- Expertise in balancing durability with surface precision

- Advanced coatings tailored for non-ferrous processing environments

- Fast turnaround to minimize impact on production schedules

- Proven track record with coil producers, rolling mills, and finishing lines

- Significant savings compared to sourcing new rollers or OEM refurbishment

Our Services

Expansive in-house capabilities allow us to keep all facets of the chrome plating and repair process under our control.