Dozer Component RemanufacturingExtending the Life of Critical Undercarriage & Hydraulic Systems

Dozers are built to withstand relentless pushing, ripping, and grading in demanding environments like mining, quarrying, and heavy construction. But even the toughest machines face wear—especially in high-stress components exposed to constant load, abrasion, and impact.

We engineer specialized remanufacturing solutions to restore and enhance key dozer components, helping you avoid costly OEM replacements and reduce equipment downtime.

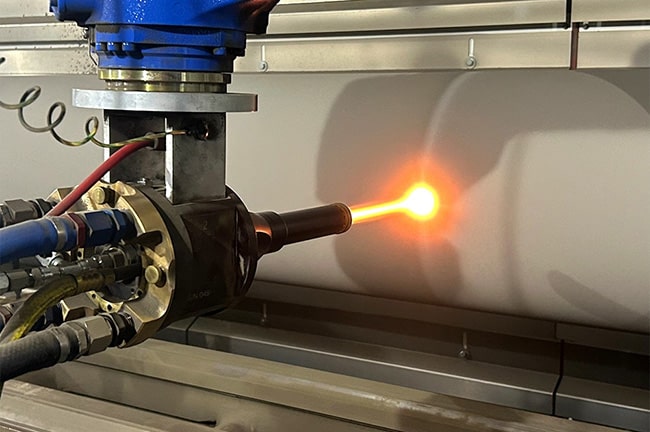

We service components from leading manufacturers, including Caterpillar, Komatsu, and other major OEMs—bringing worn parts back to life with advanced weld overlay, thermal spray coatings, and hard chrome plating.

Common Dozer Components We Remanufacture

- Pivot Shafts

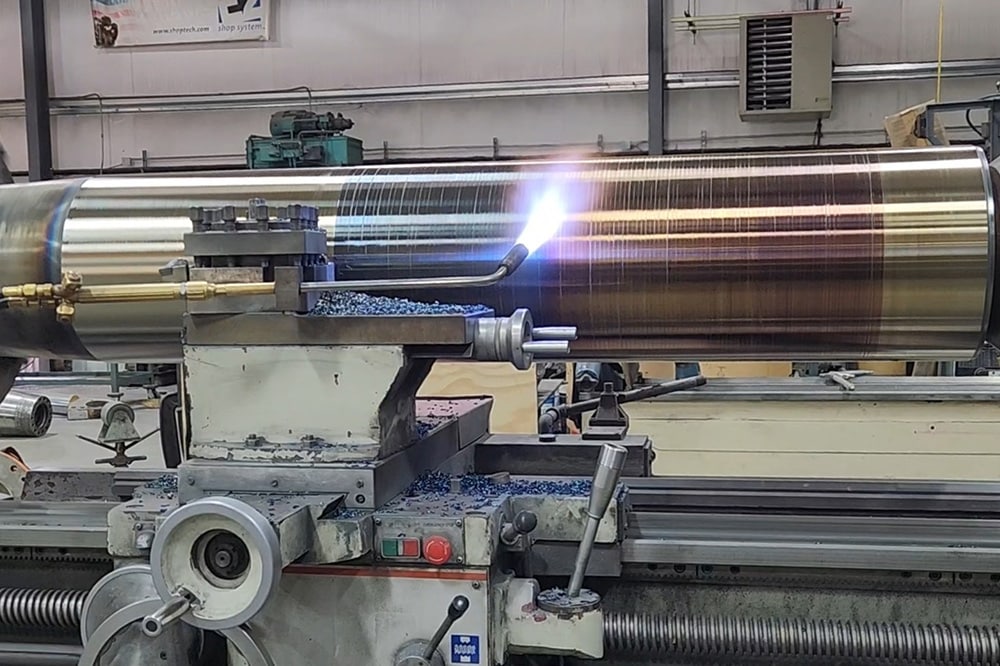

- Hydraulic Cylinder Rods (Blade Lift/Tilt Rods, Ripper Rods)

Our metallurgical repair processes restore critical tolerances, improve wear resistance, and ensure your dozer stays productive in the field—whether it’s a CAT D9/D10/D11 or a Komatsu D375/D475.

Why Partner with Us for Remanufacturing?

- Cost-Effective Repairs vs. OEM part replacement

- Expertise in base material reman – resetting life cycles to hour zero

- Enhanced durability with HVAF/HVOF coatings and weld overlays

- Fast, reliable turnaround to keep machines working

Our Services

Expansive in-house capabilities allow us to keep all facets of the chrome plating and repair process under our control.