Pivot Shaft RemanufacturingRebuilding Undercarriage & Articulation Systems for Maximum Durability

Pivot shafts are essential to the structural integrity and movement of heavy equipment, especially in dozers, wheel loaders, and articulated trucks. These shafts endure constant load, rotation, and environmental exposure—leading to wear on bearing surfaces, journals, and seal areas. Left unchecked, worn pivot shafts can result in misalignment, excessive play, and costly downtime due to premature component failure.

We remanufacture pivot shafts for mining, quarrying, and construction equipment. Our advanced processes restore critical dimensions, reinforce worn areas, and apply protective coatings to extend service life well beyond standard repairs.

Common Pivot Shaft Applications

- Dozer Equalizer Bar Pivots

(CAT D9/D10/D11, Komatsu D375/D475) - Wheel Loader Center Pivot Shafts

(CAT 988/992, Komatsu WA600/WA900)

Our Pivot Shaft Remanufacturing Solutions:

-

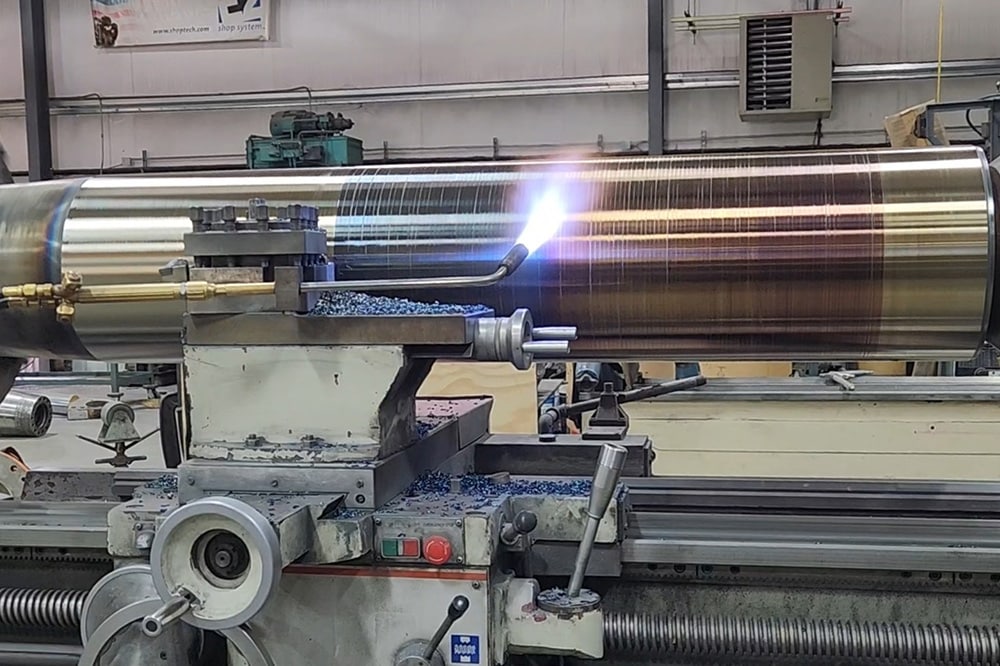

Weld Overlay for Diameter Restoration

Submerged arc welding to rebuild worn journals and bearing surfaces. -

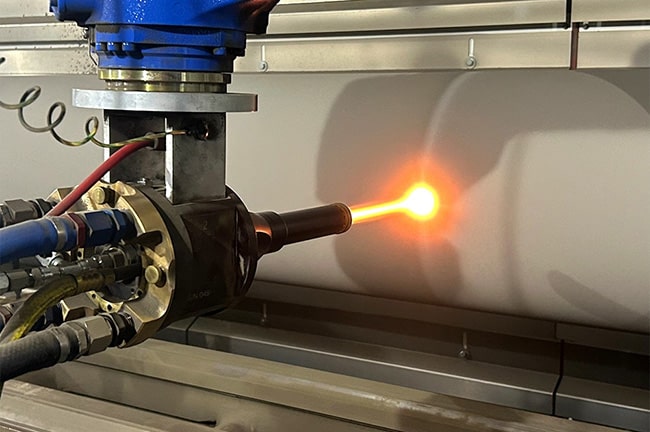

Thermal Spray Coatings (HVAF/HVOF)

Application of wear-resistant carbide coatings for extended durability in high-friction areas.

Why Trust High Tech Reman with Pivot Shaft Remanufacturing?

- Expertise in base material remanufacturing of high-load articulation points

- Advanced processes to handle severe wear—not just minor resurfacing

- Proven results in extending life for mining and construction equipment pivots

- Faster, more economical than sourcing OEM replacements

- Support for large-diameter shafts and complex geometries

Our Services

Expansive in-house capabilities allow us to keep all facets of the chrome plating and repair process under our control.