Wheel Loader Component Remanufacturing Restore Performance. Reduce Downtime. Extend Service Life

Wheel loaders are essential across mining, quarrying, construction, and material handling operations—built for high-load, repetitive cycles in abrasive environments. Over time, critical components like hydraulic systems, pivot points, and spindles face significant wear, leading to costly repairs or replacements if not properly maintained.

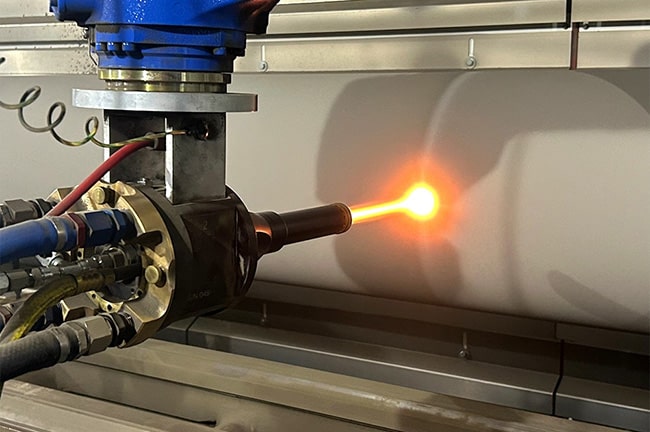

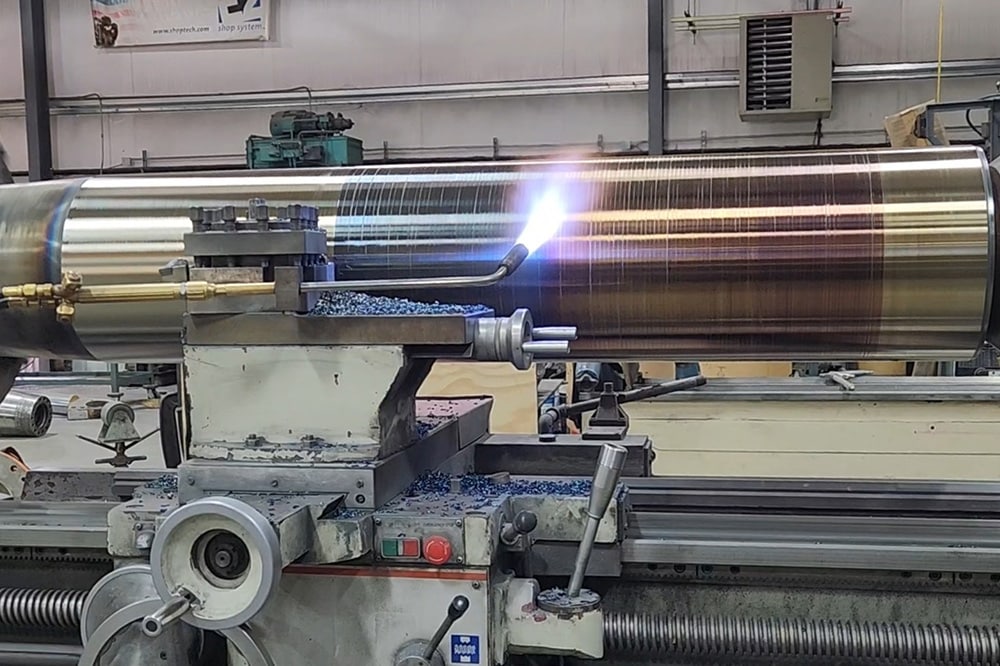

We remanufacture high-wear wheel loader components, helping fleets avoid expensive OEM replacements and extend the life of their equipment through advanced weld overlay, thermal spray coatings (HVAF/HVOF), and hard chrome plating.

We service major OEMs, including Caterpillar, Komatsu, and others—delivering durable, cost-effective solutions for loaders operating in the toughest conditions.

Common Wheel Loader Components We Remanufacture

- Hydraulic Cylinder Rods (Lift/Tilt Cylinder Rods, Steering Rods)

- Wheel Spindles

- Brake Components

Our processes restore worn surfaces, improve resistance to abrasion and corrosion, and ensure your wheel loaders—whether CAT 988/992/994 or Komatsu WA600/WA900—stay productive and reliable.

Why Choose Us for Wheel Loader Remanufacturing?

- Fast Turnarounds to minimize machine downtime

- Proven methods for lift and tilt base material restoration and spindle remanufacturing

- Enhanced wear protection with HVAF/HVOF coatings and precision weld overlays

- Support for both mining-class loaders and construction fleets

Our Services

Expansive in-house capabilities allow us to keep all facets of the chrome plating and repair process under our control.