Excavator Component RemanufacturingOptimizing Hydraulic & Pivot System Performance for Heavy-Duty Excavators

Excavators are critical assets across construction, mining, and quarry operations—performing under constant stress in abrasive, high-load environments. Key components like hydraulic cylinder rods, booms, arms, and pivot points are prone to wear, risking costly downtime and premature failure if not properly maintained.

At High Tech Reman, we provide specialized remanufacturing services to restore essential excavator components, reducing reliance on expensive OEM replacements and extending equipment life through advanced surface engineering techniques.

We support a wide range of excavators from leading OEMs, including Caterpillar, Komatsu, and others—delivering precision repairs backed by years of metallurgical expertise.

Common Excavator Components We Remanufacture

- Hydraulic Cylinder Rods (Boom, Arm, Bucket, Track Adjuster, Blade)

- Pins & swivel units

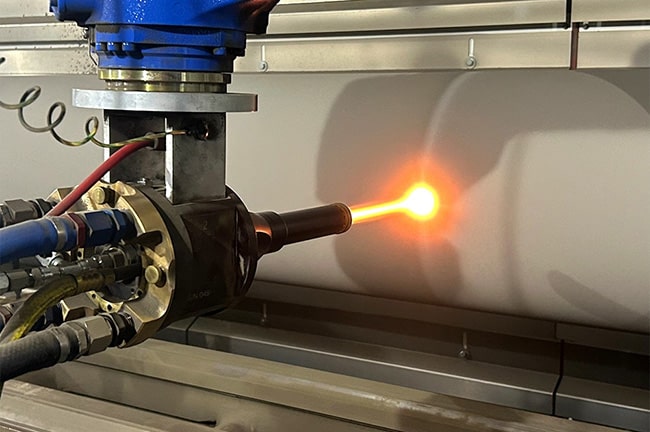

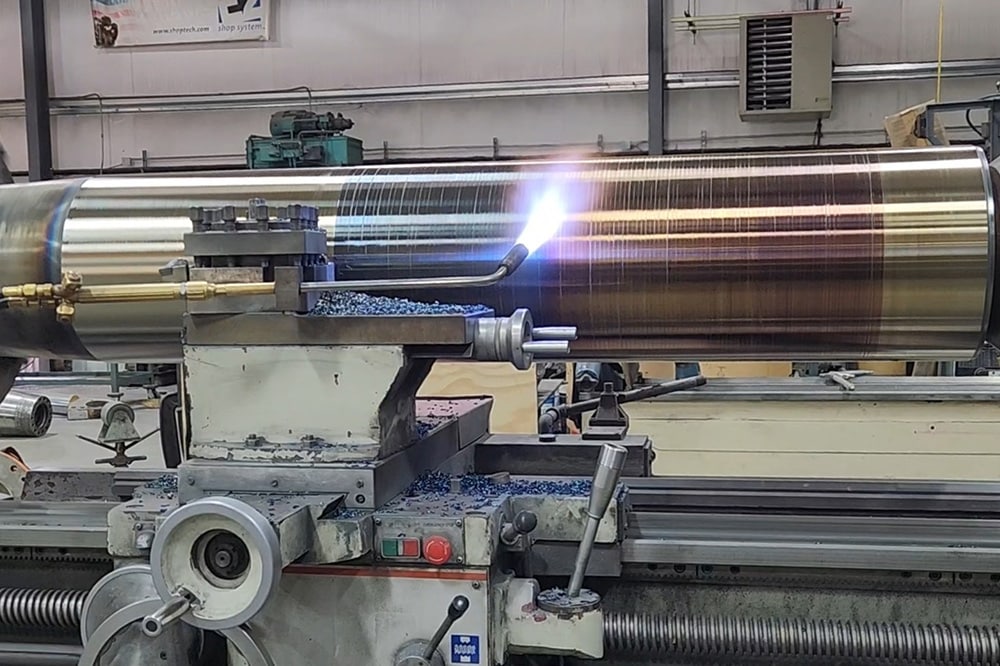

Our combination of hard chrome plating, thermal spray coatings (HVAF/HVOF), and weld overlay restores critical dimensions, enhances wear resistance, and ensures your excavators—from standard construction models to large mining-class units—stay operational longer.

Why Choose Us for Excavator Remanufacturing?

- Significant cost savings vs. OEM part replacement

- Expertise in hydraulic system restoration and pivot wear solutions

- Advanced coatings for abrasion and corrosion protection

- Fast, reliable service for both construction fleets and mining operations

Our Services

Expansive in-house capabilities allow us to keep all facets of the chrome plating and repair process under our control.