Suspension Cylinder Rod RemanufacturingExtending the Life of Haul Truck & Heavy Equipment Suspension Systems

Suspension cylinder rods play a critical role in the performance and safety of off-highway haul trucks and other heavy equipment. Operating under extreme loads, harsh environments, and constant movement, these rods are highly susceptible to wear, corrosion, pitting, and scoring—leading to costly downtime if not addressed properly.

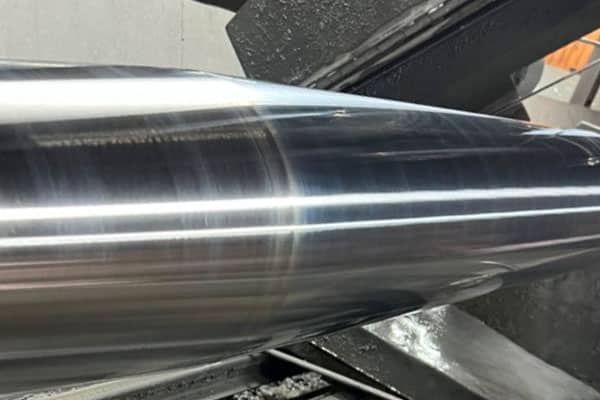

Our specialty is the complete remanufacturing and surface restoration of suspension cylinder rods for mining trucks, quarry equipment, and large construction fleets. Over nearly 4 decades, our proprietary processes have restored over 6,000 suspension rods to hour zero. They often perform better than OEM replacements—delivering extended service life and reducing replacement costs.

Common Issues We Repair

- Coating wear or delamination

- Corrosion and pitting from harsh environments

- Scoring from contaminated hydraulic systems

- Undersize rods due to repeated service cycles

- Surface damage from improper handling or installation

Supported Equipment

- Caterpillar: 769, 772, 773, 775, 777, 785, 789, 793, 797

- Komatsu: 830, 860, 930, 960, 980

Why Choose High Tech Reman?

- Safe, field-tested remanufacturing solutions

- Expertise in deep repair (weld + coat) for rods beyond standard re-chrome limits

- Potential for exchange program availability on common models

- Backed by years of proven performance in mining and heavy equipment sectors

Our Services

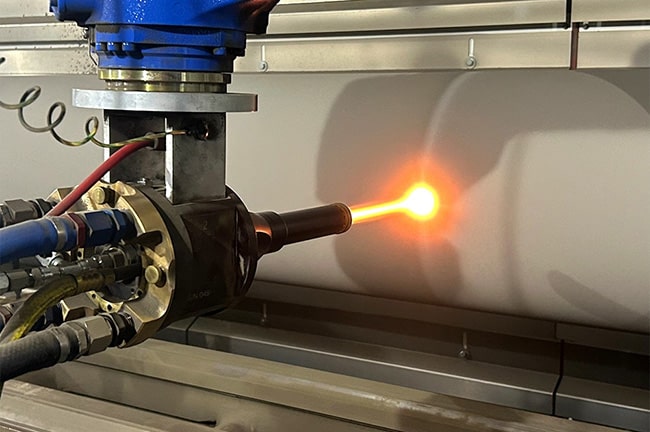

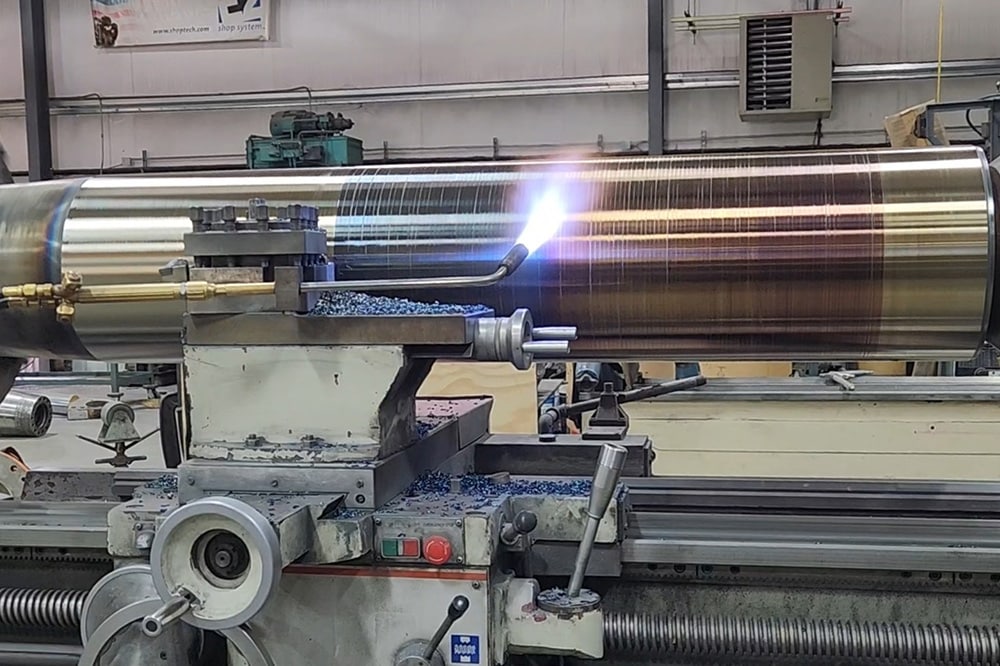

Expansive in-house capabilities allow us to keep all facets of the chrome plating and repair process under our control.